Assembly

The ideal assembly line is meant to be flexible with the ability to expand or contract to suit the frequently changing work and product requirements. Our AGVs provide this flexibility for constantly changing environments.

Daifuku’s cost-effective assembly solution has been implemented across various industries, including automotive, recreational vehicle, appliances, and farm machinery. No matter what product you are building, we have the ability to customize an assembly solution that works for your company.

M100-TT Farm Equipment Assembly Line

Equipped with a lift deck, this M100-TT AGV moves farm equipment components through multiple assembly station allowing the load handling frame to be raised or lower to improve the ergonomics for the line workers. Once the assembly is complete the product is lifted from the load handling frame and the AGV returns to the load station in the assemble process.

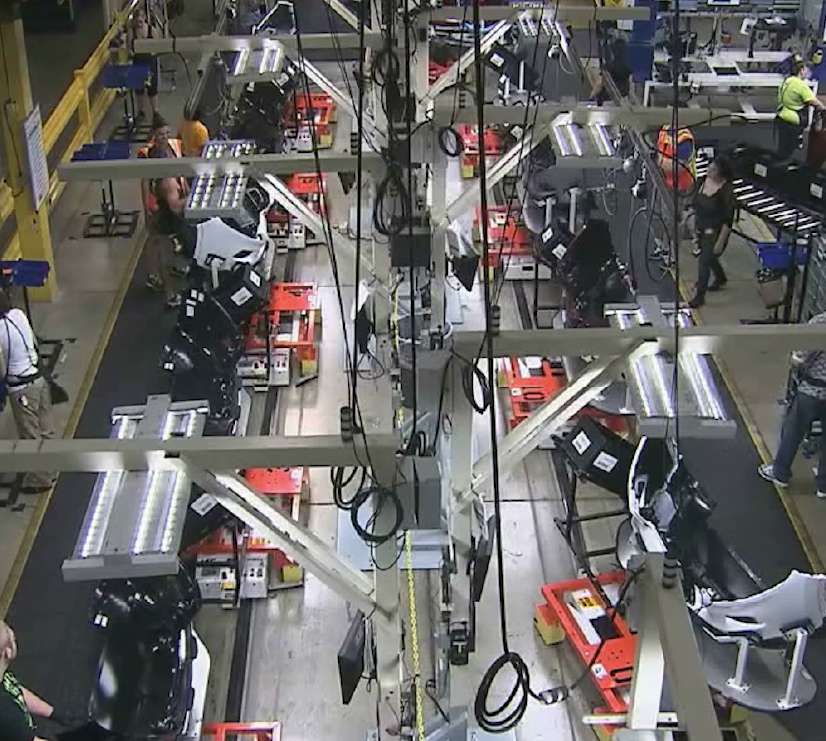

M100-TT Tunnel Tugger Automotive Front Module Assembly

Automotive front modules are assembled on special load handling frames moving through an “index and creep” loop path. All carts in the system index to the next station in unison after a prescribed amount of time has elapsed for the assembly “dwell” period.

M100-TT Automotive Line Kit Delivery

Custom roller conveyors on this M100-TT deliver specialized component kit stands to the assembly line two at a time. Once delivered the AGV backs away from the delivery roller conveyor and returns to the pick-up station.

M100-TT Automotive Parts Handling

Tunnel/tugger and rear towing AGV move various automotive components throughout this assembly plant delivering components to assembly stations and returning empty racks and carriers to their staging locations.

M200-AL Lifting Assembly Vehicle

This AGV with an assembly lifting/rotator deck moves motorcycles through complete assembly and testing. Allowing for ergonomic assembly for the line workers. Finished motorcycles are lifted from the AGV and crated for shipping.

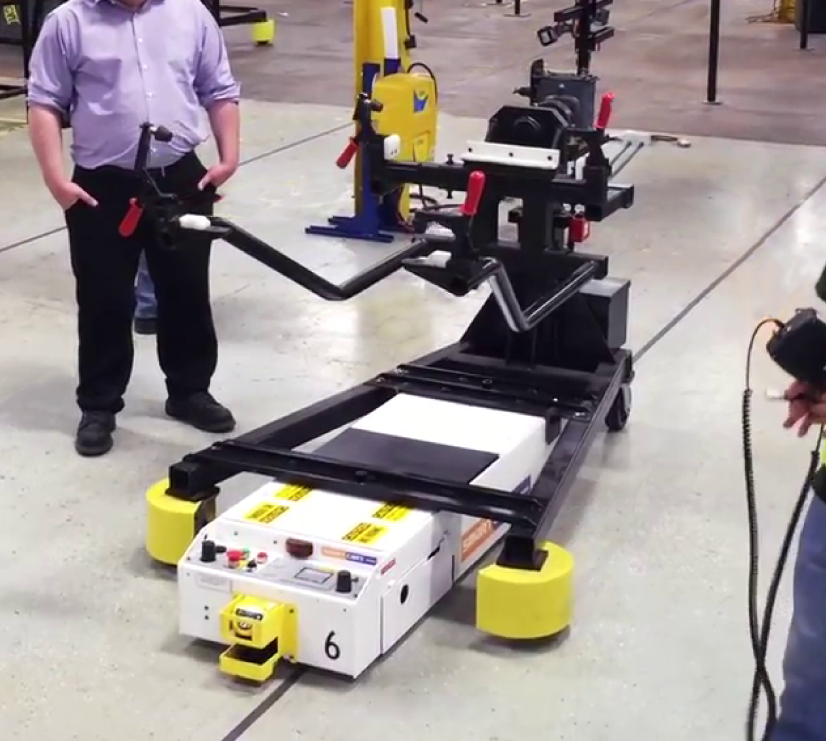

M250-AL Lifting

The wider base of this M250-AL allows for stable transport of loads that are larger than the AGV. The lifting frame allows for elevating the vehicle during assembly.

Custom M300-T with Lift and Rotator

This custom M300-T with rotator head and lift enables the marine motor to be assembled and water tested while still attached to the AGV. Once testing is complete the motors go to the final shell assembly.

M300-SC Roller Conveyor Pallet Delivery

This single roller conveyor deck AGV brings empty bulk containers to the production area and deposits them on a roller conveyor line. It then moves to a pick-up station to load a full container and moves it to the next process location.

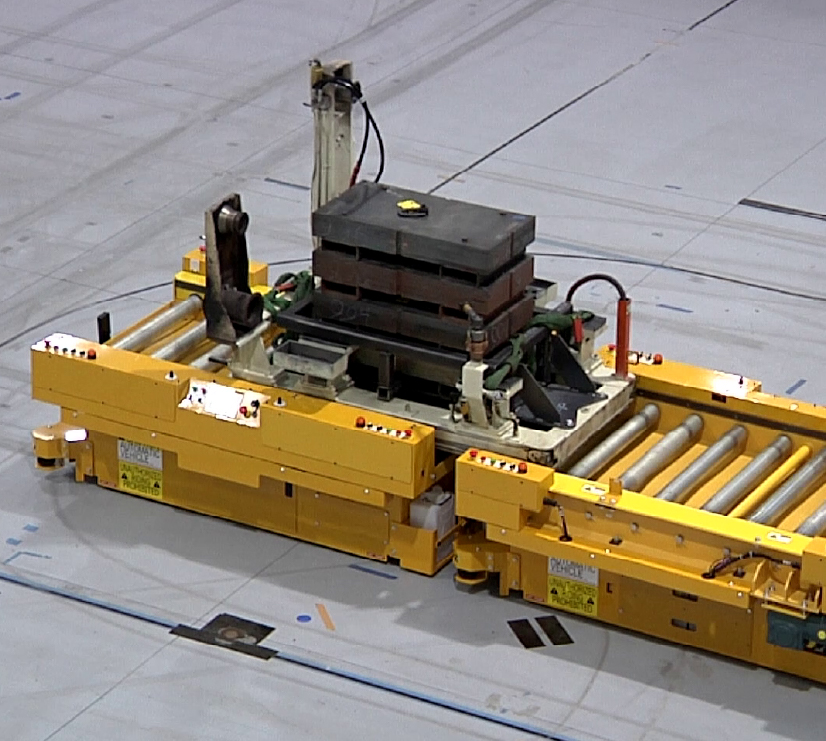

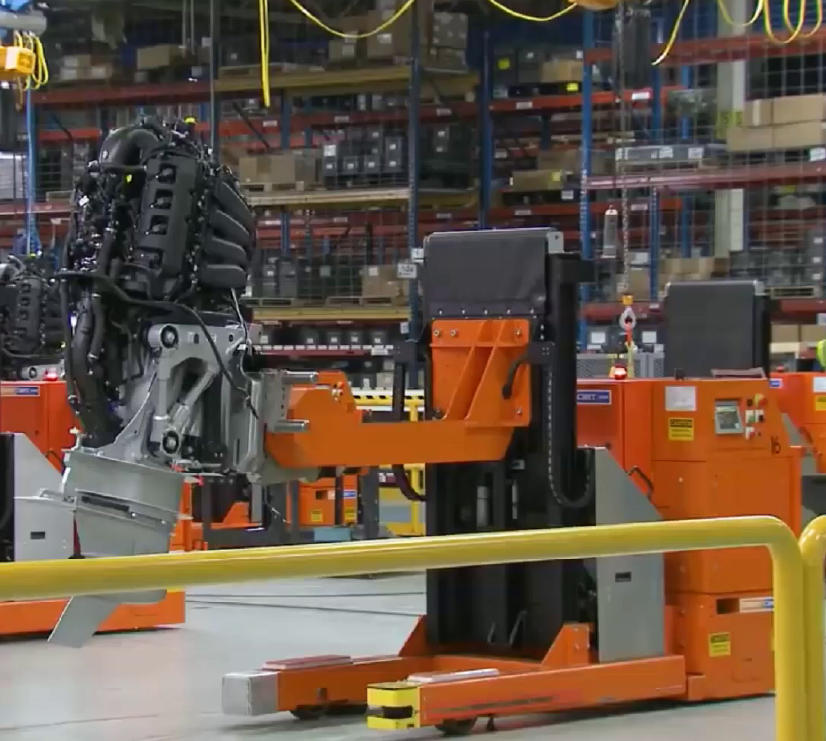

M500-A Assembly Vehicle

These “fixed frame” assembly AGVs follow a continuous assembly path for large motor assembly. Once finished in the area the motors are transported to testing.

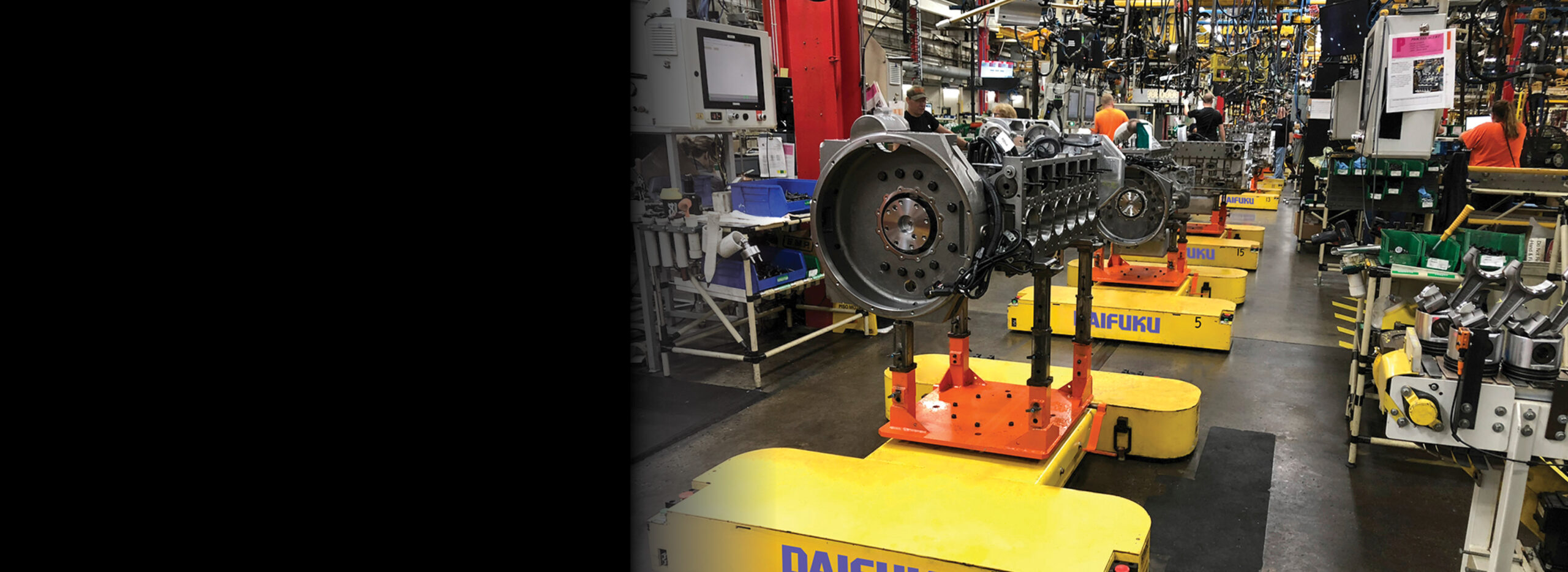

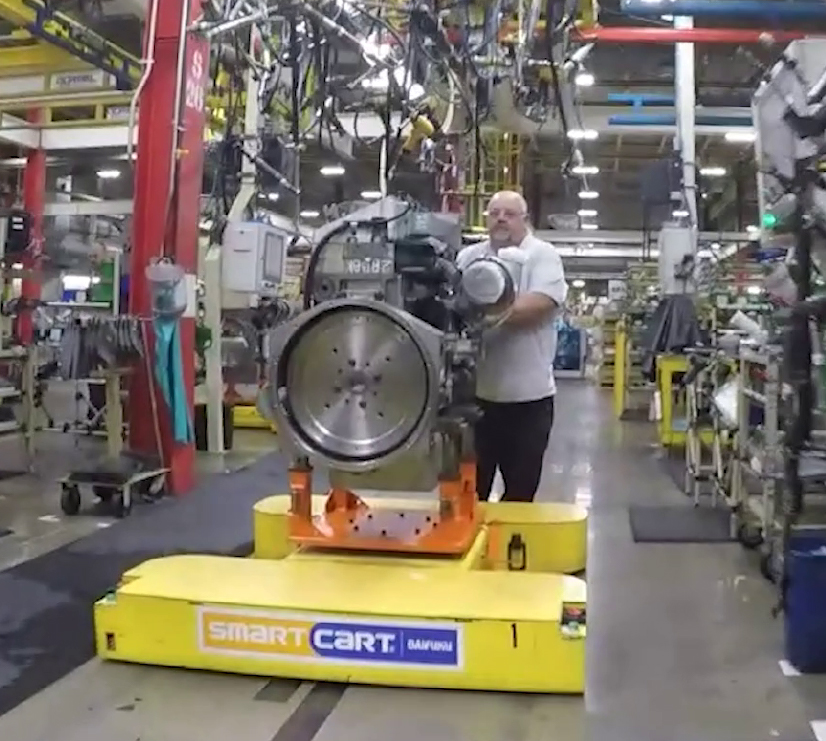

M1000-AL Engine Assembly

Large truck motors move through final trim utilizing the lift deck for better worker ergonomics and towing a component cart with all necessary components to complete this build stage.

M100-TT Tunneling with Inertial Navigation

M100-TT with fixture for Lawn Mower Assembly Line

M200-A Continuous Moving Motorcycle Assembly Line

M200-A Motorcycle Assembly Line for Index and Dwell

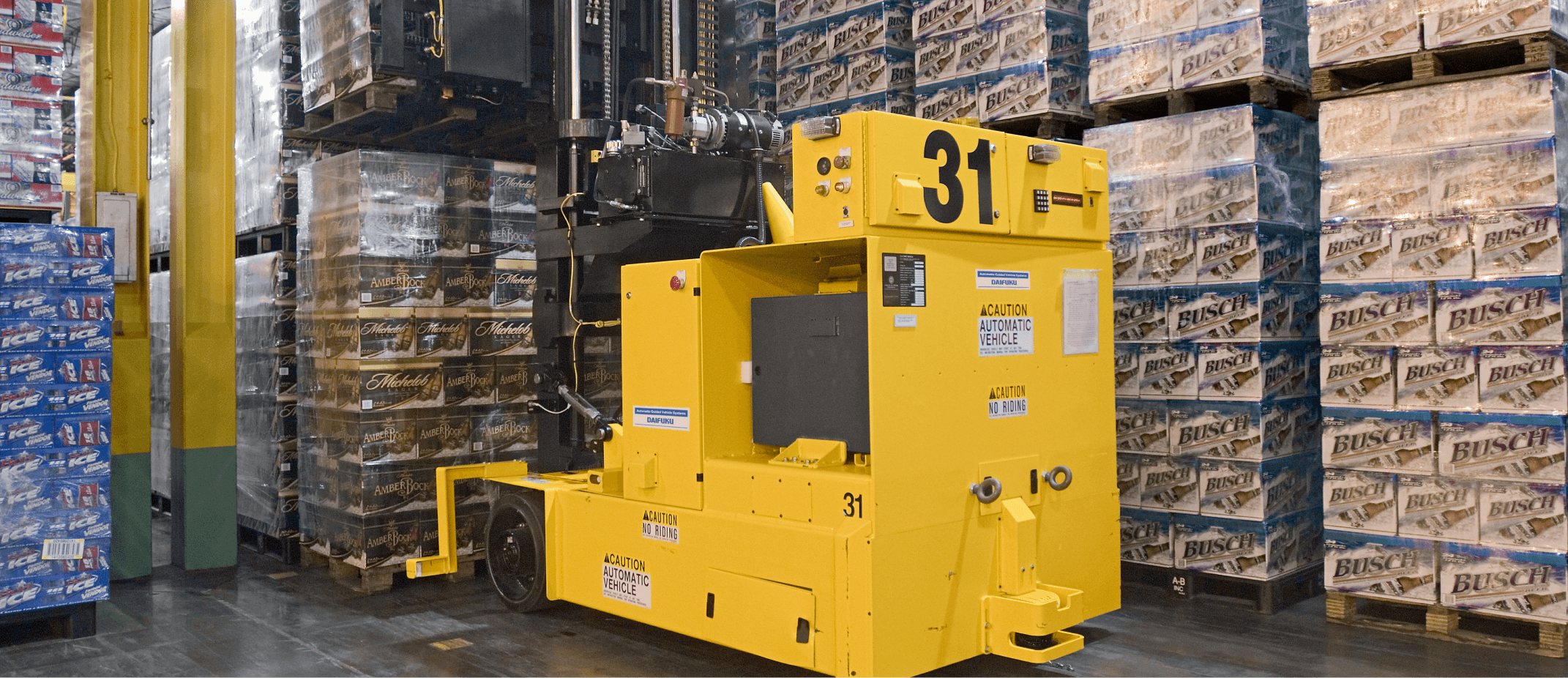

M300-CF Forked AGV for End of Line Production

Get In Touch

Discover how Daifuku can support you and your company. Send us a message to discuss our AGV solutions.