M100-TT with Auto Couple Decouple Towing Hitch

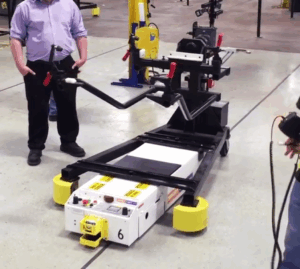

M100-TT with fixture for Lawn Mower Assembly Line

M100-TT Tunneling with Inertial Navigation

M100-TT Lane Based Storage

Seat frames are carried eight at a time on specialized load handling carriers to storage/staging lanes. M-100-TT AGVs “tunnel” through the line of carriers, picking up the last one in line. Once attachment is confirmed the carrier is taken to the assembly line.

M100-TT Automotive Parts Handling

Tunnel/tugger and rear towing AGV move various automotive components throughout this assembly plant delivering components to assembly stations and returning empty racks and carriers to their staging locations.

M100-TT Automotive Line Kit Delivery

Custom roller conveyors on this M100-TT deliver specialized component kit stands to the assembly line two at a time. Once delivered the AGV backs away from the delivery roller conveyor and returns to the pick-up station.

M100-TT Tunnel Tugger Automotive Front Module Assembly

Automotive front modules are assembled on special load handling frames moving through an “index and creep” loop path. All carts in the system index to the next station in unison after a prescribed amount of time has elapsed for the assembly “dwell” period.

M100-TT Line Kit Pick and Delivery

This tunnel/tugger AGV engages a set of carts for automotive component kitting. Once the kitting process is complete the AGV takes the carts to an assembly line side. Full carts are delivered to a staging area and then the AGV picks up a set of empty carts and returns them to the kitting station.

M100-TT Farm Equipment Assembly Line

Equipped with a lift deck, this M100-TT AGV moves farm equipment components through multiple assembly station allowing the load handling frame to be raised or lower to improve the ergonomics for the line workers. Once the assembly is complete the product is lifted from the load handling frame and the AGV returns to the load station in the assemble process.

M100-ST Tote Handling

The M100-ST nimbly maneuvers through a small component assembly and testing system. Dual roller conveyors on the load handling frame deliver and retrieve totes to assembly and testing stations.

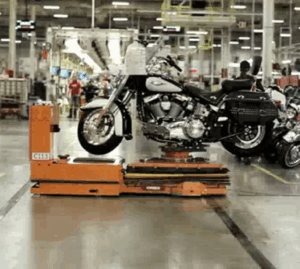

M200-A Continuous Moving Motorcycle Assembly Line

M200-A Motorcycle Assembly Line for Index and Dwell

M200-AL Lifting Assembly Vehicle

This AGV with an assembly lifting/rotator deck moves motorcycles through complete assembly and testing. Allowing for ergonomic assembly for the line workers. Finished motorcycles are lifted from the AGV and crated for shipping.

M250-AL Lifting

The wider base of this M250-AL allows for stable transport of loads that are larger than the AGV. The lifting frame allows for elevating the vehicle during assembly.

M300-CF Forked AGV for End of Line Production

M300-SC Roller Conveyor Pallet Delivery

This single roller conveyor deck AGV brings empty bulk containers to the production area and deposits them on a roller conveyor line. It then moves to a pick-up station to load a full container and moves it to the next process location.

M300-T Furniture Transport

The AGVs in this furniture warehouse move up to eight carts throughout the warehouse. Stopping at specified location for furniture loading and then transport of the full carts to the out-bound truck trailer loading location.

M300-TT Component Delivery

M300-TT AGVs engage large load handling frames to move various sized loads throughout the assembly and storage processes. Loads are removed from the load handling frames by fork trucks as necessary.

M300-TTR Transfer Vehicle

These synchronized AGVs transfer large truck frames through sequential assembly processes until they’re deposited onto wheeled carts for removal from the assembly area.

Custom M300-T with Lift and Rotator

This custom M300-T with rotator head and lift enables the marine motor to be assembled and water tested while still attached to the AGV. Once testing is complete the motors go to the final shell assembly.

M500-A Assembly Vehicle

These “fixed frame” assembly AGVs follow a continuous assembly path for large motor assembly. Once finished in the area the motors are transported to testing.

M500-A Roller Conveyor Transfer Vehicle

The M500-A transfer vehicle enables movement, testing and transfer of large motors during the assembly process. The sealed tray below the roller conveyor controls any fluid loss during testing and has drain ports for easy removal of the waste fluids.

M500-U Unit Load with Lift Deck

These lift deck equipped AGVs move throughout this 1 million sq ft warehouse automatically transporting palletized loads to stretch wrappers or individual components to consolidation stations for bulk packaging.

M1000-AL Engine Assembly

Large truck motors move through final trim utilizing the lift deck for better worker ergonomics and towing a component cart with all necessary components to complete this build stage.

Custom AGV Dual Roller Conveyor

This dual roller conveyor AGV transports stretched pallets of food products to staging gravity fed roller conveyors for eventual rack storage. These AGVs coexist with constant fork truck traffic delivering their loads and returning to the stretch wrap pick up location.

M3K-CF-L Counterbalanced Fork

These counterbalanced fork AGVs repetitiously pick up full pallet loads of material from robotic stations and transport them to chain conveyor drop station for stretch wrapping.

M8K-PJ Pallet Jack Deep Lane Storage

These pallet jack AGVs move wire bins and pallet loads throughout the facility. Placing loads into deep lane storage for retrieval as needed.

M10K-T Roller Conveyor Cart Train

This tugger AGV moves a “train” of roller conveyor carts to drop off locations and, when empty, returns the train of carts back to the pick-up area.

M40K-T AGV Turn and Stop Testing

SL-7000 AGV Warehouse and Trailor Loading System

M10K-T Tugger

These tuggers automatically engage the loads to be moved and transport them to their next process point. Returning either for a new load or to the charging station.

SL 5000 SmartLoader Dual Fork

This dual forked AGV transports dual double stacked pallets of empty beverage containers. These loads are automatically stacked into a warehouse until needed for beverage production.

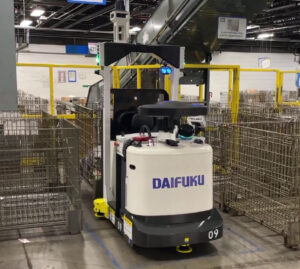

Get in Touch

Discover how Daifuku can support you and your company. Send us a message to discuss AGV solutions.